The corona gun is most often made use of and works on imparting a adverse electrostatic charge for the powder particles. Just after getting the charge, these particles are shot within the component being coated by way of compressed air or mechanical action.

Just after applying the coat but just before curing, be careful to not brush or blow within the powder coat, as this may bring about many of the powder to drop off, leaving you having a a lot less exact coat.

Powder coating is available in several colors and surface area finishes. It's Consequently suited to a variety of architectural and aesthetic programs. This permits for layouts that include the structural energy of metals, paired with the aesthetic complete of any coloration and texture.

Submerging: The element stays submerged inside the fluid bed to enable the powder paint to make a thick, wear-resistant coating. The ultimate thickness with the coating depends upon the initial warmth of the item just before immersion as well as the period it spends during the fluidized bed of powder coating.

Powder coated items commonly have much less visual appeal discrepancies than liquid coated products amongst horizontally coated surfaces and vertically coated surfaces.

Electrostatic magnetic brush, or EBM, coating is fairly new and works on identical rules as a copier machine.

The curing time for powder coating is much shorter than that necessary for traditional paint. This can be las vegas powder coating especially true in apps making use of UV curing or Sophisticated low-bake thermosetting powders.

Mechanical cleaning may be used independently or along with a chemical cure. Although it improves adhesion, it doesn't provide supplemental corrosion security.

A coating system for flat components that applies powder having a roller, enabling relatively superior speeds and accurate layer thickness between 5 and a hundred micrometres. The bottom for this process is traditional copier engineering.

Nonetheless, the achievements of these kinds of coatings depends on the material remaining coated and the sort of powder utilized. Therefore, powder coating on non-conductive products is really a specialized method that requires careful consideration.

This really is the initial step in the procedure. If you don't have access to a sandblaster, you can also make use of a wire wheel, bench-grinder, or simply sandpaper. Just providing you get the material down to bare metal. The following stage is always to strip the metal of any remaining grime or gunk. You could reach this by soaking the product in acetone (When the merchandise is sufficiently small) or by wiping it with the acetone-soaked rag.

Drying: Effectively dry the substrate to avoid the formation of water spots or floor defects while in the powder coating. Air drying, oven drying, or forced air drying may be used, with regards to the substrate and facility’s abilities.

Tribo Charging Spray Guns: In such a gun, powder particles acquire their electrostatic demand by way of friction when they rub versus a sound insulator or conductor inside the gun. This process leads to positively billed powder particles eradicating the Faraday's cage impact - a common trouble with Corona guns, which makes it perfect for coating complex styles.

Powder coating is actually a finishing technique that actually works very well with metals because of the ability of metals to easily hold an electrical cost. This charge permits a dry polymer resin to persist with the metal floor right before being cured under heat, creating a tricky and smooth end.

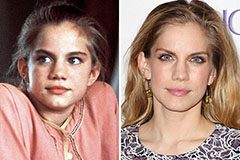

Anna Chlumsky Then & Now!

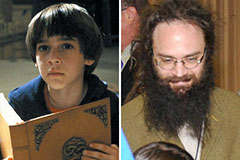

Anna Chlumsky Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Patrick Renna Then & Now!

Patrick Renna Then & Now! Jenna Jameson Then & Now!

Jenna Jameson Then & Now! Naomi Grossman Then & Now!

Naomi Grossman Then & Now!